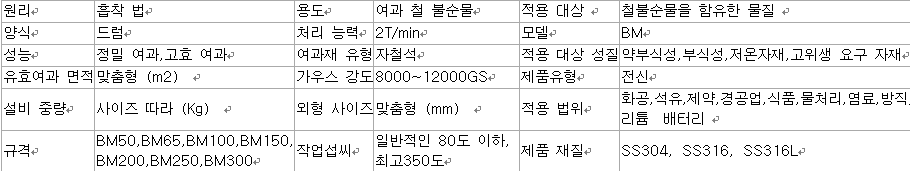

Permanent magnetic container :

Permanent Self-Design System Iron impurities among dry powder and granular materials, usually installed gravity pipes or full-combination pipes.

For example, iron debris, nuts, screws, bolts, high quality materials, and downstream production processing facilities are protected.

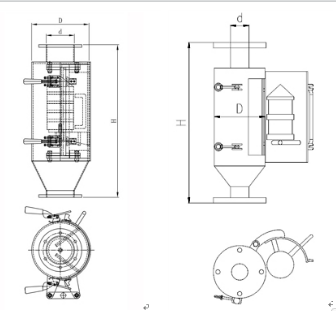

Structure :

A permanent magnetic canister consists of a stainless steel casing and a design of a bullet-shaped cone, a permanent magnetic cylinder with strong magnetic force, which makes it easier for the material to pass through.

Features :

1. Box surface treatment : Not boring, Sand Plast treatment

2. Box material : SUS 304

3. Magnetic field strength : Various magnetic intensity can be selected

4. Customize designs according to application requirements

|

Model |

Size(mm) |

|

d |

D |

H |

|

BM50 |

51 |

114 |

380 |

|

BM65 |

76 |

168 |

540 |

|

BM100 |

108 |

219 |

586 |

|

BM150 |

159 |

273 |

655 |

|

BM200 |

219 |

325 |

760 |

|

BM250 |

273 |

426 |

850 |

|

BM300 |

325 |

480 |

880 |

Description : BM : Permanent Self-inalysis

Application :

Suitable treatment powder, granules, applied food, food, feed, chemicals, etc.

Cleaning :

Fixed to the vertebral core stainstrics door, opening of the door, concurrent core movement pipe, and then, iron impurities and steel impurities treated to the core surface being treated were dropped into the production line.Effective damage recontamination material.

When ordering, you order :

1. Type and size of discharge

2. Pipe Pressure

3. Work temperature

4. Floor Space Limits

5. Magnetic field strength

6. Material characteristics, material name, pieze, granulence, flow rate, etc.

7. Special design

|